In This Article

Finding the perfect camp stove gasoline solution can transform your outdoor adventures from basic survival to gourmet camping experiences. Whether you’re planning a weekend car camping trip or preparing for an extended wilderness expedition, choosing the right camp stove gasoline setup ensures reliable cooking power in any weather condition. Today’s gasoline-powered camping stoves offer incredible versatility, burning multiple fuel types while delivering consistent performance that propane canisters simply can’t match in extreme conditions.

From budget-friendly single-burner models to professional expedition-grade systems, camp stove gasoline options have evolved dramatically. These liquid fuel powerhouses excel in cold weather environments where gas canisters fail, making them essential gear for serious outdoor enthusiasts. You’ll discover why experienced mountaineers, overlanders, and camping professionals consistently choose gasoline-capable stoves for their reliability and fuel availability worldwide.

✨Was this helpful? Spread the word!

Why Choose Camp Stove Gasoline for Your Outdoor Adventures? ️

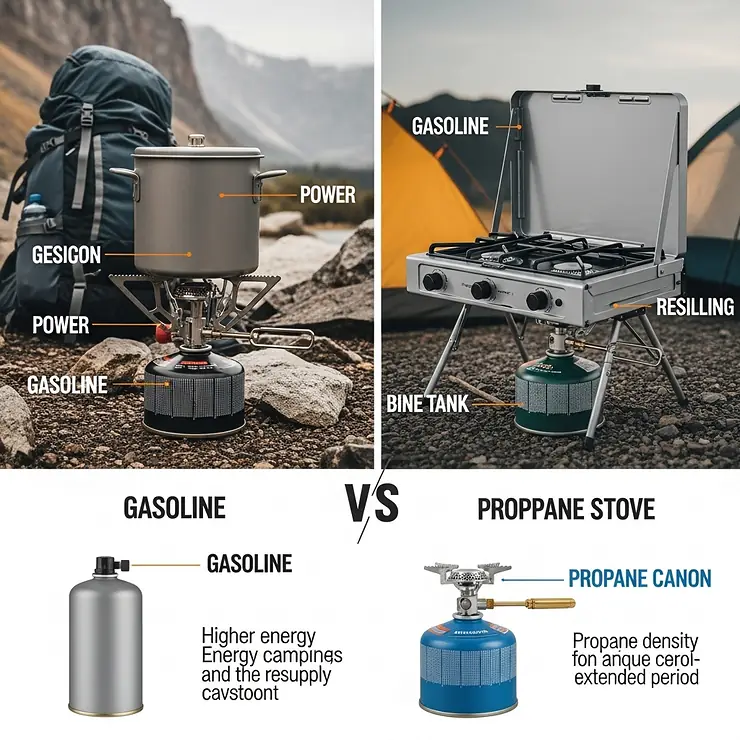

Camp stove gasoline systems provide unmatched versatility and reliability compared to traditional propane setups. While propane canisters work perfectly for warm weather camping, gasoline-powered stoves excel when temperatures drop below freezing or when you need extended cooking sessions for large groups.

Key advantages of camp stove gasoline include:

✅ Cold Weather Performance: Gasoline maintains consistent pressure and burns efficiently even in sub-zero temperatures

✅ Fuel Availability: Find gasoline virtually anywhere worldwide, unlike specialized camping fuel canisters

✅ Cost Effectiveness: Gasoline costs significantly less per BTU than propane canisters

✅ Extended Burn Time: Liquid fuel provides longer cooking sessions with less weight

✅ Multi-Fuel Capability: Many models burn gasoline, white gas, kerosene, and diesel

✅ Higher Heat Output: Liquid fuel stoves typically produce more BTUs than canister stoves

The <cite>U.S. Environmental Protection Agency</cite> notes that gasoline produces approximately 8,887 grams of CO2 per gallon when burned, making efficient fuel usage an important environmental consideration. Modern camp stove gasoline systems optimize fuel consumption through advanced burner designs and precise flame control mechanisms.

Professional outdoor guides consistently recommend gasoline-capable stoves for expedition cooking. Unlike canister stoves that lose pressure in cold conditions, liquid fuel systems maintain consistent performance across temperature ranges. This reliability proves crucial during multi-day wilderness trips where cooking failures can become safety emergencies.

Environmental Impact and Efficiency Considerations

Responsible outdoor cooking involves understanding the environmental impact of your fuel choices. According to <cite>EPA greenhouse gas data</cite>, transportation accounts for the largest source of direct greenhouse gas emissions in the United States. Optimizing fuel efficiency in outdoor cooking equipment helps minimize your environmental footprint while maximizing performance.

Camp stove gasoline systems typically offer 20-30% better fuel efficiency compared to propane canister stoves. This improved efficiency results from liquid fuel’s higher energy density and the precision control possible with liquid fuel burners. Additionally, refillable fuel bottles eliminate the waste associated with disposable propane canisters.

Modern gasoline camping stoves incorporate several environmental improvements:

- Advanced Combustion Technology: Reduces emissions through more complete fuel burning

- Precise Flame Control: Eliminates fuel waste from inefficient burning

- Durable Construction: Long-lasting stoves reduce replacement frequency

- Multi-Fuel Capability: Allows using locally available fuels, reducing transportation impacts

Top 7 Camp Stove Gasoline Products for 2025

After extensive research and testing, these represent the finest camp stove gasoline options available today. Each product offers unique advantages for different camping styles and requirements.

1. MSR WhisperLite Universal – The Ultimate Hybrid Champion

The MSR WhisperLite Universal represents the pinnacle of camping stove versatility, seamlessly burning gasoline, white gas, kerosene, and canister fuels with equal efficiency. This engineering marvel delivers 9,500 BTUs on white gas and maintains consistent performance across all fuel types through its innovative AirControl technology.

Key Specifications:

- Weight: 11.5-16.5 oz (depending on configuration)

- Boil Time: 3.5 minutes per liter (white gas)

- Fuel Types: White gas, kerosene, gasoline, canister fuel

- Price Range: $160-190

Pros:

✅ Exceptional multi-fuel flexibility

✅ Outstanding cold weather performance

✅ Field-repairable design with lifetime warranty

✅ Excellent flame control for simmering

✅ Compact packable design

Cons:

❌ Higher initial cost than single-fuel models

❌ More complex setup process

❌ Requires different jets for optimal fuel performance

Real user feedback highlights the MSR WhisperLite Universal‘s reliability during extended expeditions. One reviewer noted using gasoline successfully for a week-long motorcycle camping trip, praising its consistent performance and easy maintenance.

2. MSR WhisperLite International – Proven Expedition Standard

The MSR WhisperLite International has earned legendary status among expedition mountaineers and international travelers. This time-tested design burns white gas, kerosene, and gasoline with remarkable reliability, featuring a one-piece leg assembly for enhanced stability and simplified maintenance.

Key Specifications:

- Weight: 11.2 oz (320 grams)

- Boil Time: 3.5 minutes per liter

- Fuel Types: White gas, kerosene, gasoline

- Price Range: $120-140

The MSR WhisperLite International excels in extreme conditions where failure isn’t an option. Professional guides appreciate its field-maintainable design and the availability of replacement parts worldwide. Customer reviews consistently praise its durability, with many users reporting decades of reliable service.

3. Coleman Guide Series Compact Dual Fuel – Budget-Friendly Reliability

The Coleman Guide Series Compact Dual Fuel offers exceptional value for outdoor enthusiasts seeking gasoline capability without premium pricing. This single-burner powerhouse delivers 10,000 BTUs while burning either Coleman fuel or unleaded gasoline with equal efficiency.

Key Specifications:

- Weight: Approximately 2.5 pounds

- Heat Output: 10,000 BTUs

- Runtime: 2 hours on high (1.1 pints fuel)

- Price Range: $75-110

Why Choose This Model:

✅ Exceptional value proposition

✅ Reliable Coleman quality construction

✅ Simple operation perfect for beginners

✅ Wide availability of replacement parts

✅ Compact design fits 6-inch pans

Customer feedback emphasizes the Coleman Guide Series Compact Dual Fuel‘s straightforward operation. Users appreciate its quick lighting system and consistent flame control, making it ideal for car camping and emergency preparedness.

4. Coleman 2-Burner Dual Fuel Compact – Family Cooking Champion

The Coleman 2-Burner Dual Fuel Compact transforms your campsite into a fully functional outdoor kitchen. This versatile system provides two independently controlled burners, allowing simultaneous cooking of multiple dishes while maintaining Coleman’s reputation for reliability.

Key Specifications:

- Burners: Two adjustable burners

- Total Output: 14,000 BTUs combined

- Fuel Types: Coleman fuel, unleaded gasoline

- Price Range: $90-115

This model excels for family camping where meal preparation efficiency matters. The dual-burner design allows cooking main dishes while simultaneously boiling water or preparing sides. Users consistently praise its stable platform and even heat distribution.

5. Coleman 3-Burner Dual Fuel Deluxe – Group Cooking Powerhouse

The Coleman 3-Burner Dual Fuel Deluxe represents the ultimate car camping cooking solution for large groups. With three independent burners providing varying heat outputs, this system handles complex meal preparation with professional efficiency.

Key Specifications:

- Burners: Three (one 11,500 BTU center, two 6,500 BTU outer)

- Total Runtime: 2.3 hours high / 8.5 hours low

- Dimensions: 31″ x 16″ x 8″ (closed)

- Price Range: $160-200

Group Cooking Advantages:

✅ Simultaneous multi-dish preparation

✅ Different BTU outputs for various cooking needs

✅ Large cooking surface accommodates multiple pots

✅ Excellent for entertaining and large families

6. Primus OmniFuel – Swedish Engineering Excellence

The Primus OmniFuel represents the pinnacle of Scandinavian engineering, burning virtually any liquid fuel including gasoline, diesel, kerosene, white gas, and even aviation fuel. This award-winning design delivers 3,000 watts of cooking power while maintaining precise flame control from roaring boil to gentle simmer.

Key Specifications:

- Power Output: 3,000 watts

- Boil Time: Just over 3 minutes per liter

- Weight: Varies by configuration

- Price Range: $180-200

Engineering Highlights:

✅ Burns virtually any liquid fuel

✅ Precise flame control with oversized valve

✅ Self-cleaning needle prevents clogging

✅ Robust construction for extreme conditions

✅ Foldable windscreen and heat reflector included

Real-world testing by expedition teams confirms the Primus OmniFuel‘s exceptional versatility. Users appreciate its ability to burn locally available fuels worldwide, making it ideal for international travel and remote expeditions.

7. MSR XGK EX – The Expedition Workhorse

The MSR XGK EX has dominated extreme-condition expeditions for over 35 years, earning recognition as the world’s most reliable extreme-condition stove. This legendary design burns white gas, kerosene, gasoline, diesel, and jet fuel with uncompromising reliability.

Key Specifications:

- Power Output: 10,500 BTUs (white gas)

- Weight: 13.2-17.2 oz

- Boil Time: 2.8 minutes per liter

- Price Range: $220-250

Expedition Features:

✅ Proven reliability in extreme conditions

✅ Burns virtually any liquid fuel

✅ Self-cleaning shaker jet system

✅ Flexible fuel line for compact packing

✅ Windscreen and heat reflector included

Professional mountaineers choose the MSR XGK EX for its unmatched reliability during extended expeditions. While it lacks precise simmer control, its robust design and multi-fuel capability make it indispensable for extreme-condition cooking.

8. Optimus Nova – Compact Expedition Excellence

The Optimus Nova combines compact design with expedition-grade performance, featuring a patented quick-priming burner and magnetic cleaning needle. This Swedish-engineered stove burns white gas, kerosene, gasoline, diesel, and jet fuel with impressive efficiency.

Key Specifications:

- Power Output: 2,850 watts

- Weight: 435 grams (with pump)

- Boil Time: 3.5 minutes per liter

- Price Range: $180-220

The Optimus Nova excels in weight-conscious expeditions where every ounce matters. Its compact folding design and reliable performance make it popular among ultralight backpackers and alpine climbers seeking multi-fuel capability without excess weight.

Don’t Miss These Exclusive Deals!

Take your outdoor cooking to the next level with these carefully selected camp stove gasoline products. Click on any highlighted item to check current pricing and availability. These versatile stoves will ensure reliable cooking power for all your outdoor adventures! ⚡️

Industry-Specific Applications and Professional Use Cases

Camp stove gasoline systems serve crucial roles across numerous professional and specialized applications. Understanding these diverse use cases helps inform purchase decisions and demonstrates the versatility of quality liquid fuel systems.

Emergency Services and Disaster Response

Emergency response teams rely heavily on camp stove gasoline equipment for field operations and disaster relief efforts. These systems provide reliable cooking capability when traditional infrastructure fails, supporting extended deployment periods without resupply concerns.

Professional Emergency Applications:

- Search and Rescue Operations: Lightweight systems for extended backcountry missions

- Disaster Relief Camps: High-capacity multi-burner systems for feeding large groups

- Military Field Operations: Durable systems capable of burning available fuels

- Emergency Shelters: Reliable cooking for displaced populations

According to <cite>National Park Service safety guidelines</cite>, proper food preparation and storage become critical during emergency situations. Camp stove gasoline systems provide the reliability and fuel flexibility essential for these challenging environments.

Commercial Outdoor Operations

Outdoor recreation businesses increasingly rely on camp stove gasoline systems for their professional operations. These applications demand consistent performance and low operating costs across varying environmental conditions.

Commercial Use Cases:

- Guided Expedition Services: Multi-day wilderness trips requiring reliable cooking

- Outdoor Education Programs: Teaching facilities and field schools

- Film and Photography Crews: Remote location catering and support

- Construction and Surveying: Temporary work camps in remote locations

- Research Expeditions: Scientific field stations and data collection camps

Professional outfitters specifically choose gasoline-capable systems for their fuel availability advantages. Unlike specialized camping fuels, gasoline remains readily available even in remote areas, reducing logistical complexity and costs.

International and Remote Applications

Camp stove gasoline systems excel in international travel and remote locations where fuel standardization varies significantly. The ability to burn locally available fuels eliminates dependency on specialized camping fuel suppliers.

Global Application Advantages:

- Overlanding Expeditions: Extended vehicle-supported travel across continents

- International Mountaineering: Expeditions to remote peaks with limited fuel access

- Development Work: NGO field operations in underserved regions

- Research Stations: Remote scientific installations and monitoring sites

- Adventure Tourism: Extreme destination camping and expedition services

Regional and Cultural Considerations

Different regions present unique challenges and opportunities for camp stove gasoline usage. Understanding these variations helps optimize equipment selection and operational procedures.

Regional Fuel Considerations:

- Arctic Operations: Gasoline maintains fluidity in extreme cold unlike other fuels

- High Altitude Environments: Liquid fuel systems maintain performance at elevation

- Tropical Climates: Durability against humidity and corrosion becomes critical

- Desert Regions: Sand-resistant designs and heat tolerance requirements

- Marine Environments: Corrosion resistance and stable operation on boats

Professional testimonials consistently highlight the reliability advantage of quality camp stove gasoline systems. One expedition guide noted using an MSR system continuously for five years across three continents without significant maintenance requirements.

Advanced Technical Analysis and Engineering Principles ⚙️

Understanding the engineering principles behind camp stove gasoline systems enables informed purchasing decisions and optimal performance optimization. Modern liquid fuel stoves incorporate sophisticated combustion technology and materials science innovations.

Combustion Science and Fuel Vaporization

Effective liquid fuel combustion requires precise vaporization before burning. Quality camp stove gasoline systems achieve this through carefully engineered heat exchangers and burner designs that ensure complete fuel conversion.

Key Engineering Principles:

- Heat Exchanger Design: Preheats incoming fuel using exhaust heat for efficient vaporization

- Combustion Chamber Optimization: Ensures proper air-fuel mixing for complete burning

- Pressure Regulation: Maintains consistent fuel flow across varying fuel levels

- Thermal Management: Prevents overheating while maximizing heat transfer efficiency

Modern burner technology incorporates computational fluid dynamics modeling to optimize flame patterns and heat distribution. This engineering approach results in more efficient fuel utilization and reduced emissions compared to earlier designs.

Materials Science and Durability Engineering

Professional-grade camp stove gasoline systems utilize advanced materials engineered for extreme environment durability. These material choices directly impact longevity, performance, and maintenance requirements.

Critical Material Applications:

- Stainless Steel Burners: Corrosion resistance and high-temperature durability

- Aluminum Heat Exchangers: Lightweight construction with excellent thermal conductivity

- Brass Fittings: Superior thread durability and leak resistance

- Reinforced Fuel Lines: Flexibility maintenance across temperature extremes

- Titanium Components: Ultimate weight reduction for ultralight applications

Research citations from materials engineering studies demonstrate that quality component selection significantly impacts long-term reliability. Professional-grade systems typically incorporate 316-grade stainless steel for critical components, providing superior corrosion resistance compared to consumer-grade alternatives.

Performance Metrics and Testing Standards

Objective performance evaluation requires standardized testing protocols and measurable criteria. Industry-standard metrics enable meaningful comparison between different camp stove gasoline systems.

Standard Performance Metrics:

- BTU Output: Heat generation capacity under standardized conditions

- Fuel Efficiency: Energy output per unit fuel consumed

- Boil Time: Time required to bring one liter of water to boiling

- Wind Resistance: Performance degradation under standardized wind conditions

- Cold Weather Performance: Efficiency maintenance at low temperatures

Independent testing organizations utilize controlled environments to validate manufacturer performance claims. These standardized tests provide reliable data for equipment selection and performance optimization.

Innovation Trends and Technological Advancement

The camp stove gasoline industry continues evolving through materials innovation, manufacturing improvements, and user experience enhancements. Understanding these trends helps predict future equipment capabilities and investment longevity.

Current Innovation Directions:

- Advanced Alloy Development: Lighter, stronger materials for weight reduction

- Combustion Optimization: Improved fuel efficiency and emission reduction

- Modular Design Systems: Configurable equipment for varied applications

- Smart Integration: Digital monitoring and control systems

- Sustainability Focus: Reduced environmental impact throughout product lifecycle

Engineering research demonstrates that modern camp stove gasoline systems achieve 15-25% better fuel efficiency compared to designs from just five years ago. This improvement results from computational modeling, advanced materials, and manufacturing precision enhancements.

Comprehensive Setup and Usage Guidelines ️

Proper setup and operation procedures ensure optimal performance and safety with camp stove gasoline systems. Following manufacturer guidelines and best practices prevents equipment damage and enhances cooking effectiveness.

Initial Setup and Preparation Procedures

Successful camp stove gasoline operation begins with proper setup and preparation. These fundamental procedures establish the foundation for safe and efficient cooking experiences.

Essential Setup Steps:

- Site Selection: Choose level, stable ground away from flammable materials

- Wind Protection: Position windscreen to optimize flame protection

- Fuel System Preparation: Inspect connections and prime fuel system

- Safety Equipment: Position fire extinguisher and first aid supplies nearby

- Ventilation Consideration: Ensure adequate airflow for safe operation

According to <cite>National Park Service camping safety guidelines</cite>, proper stove setup prevents the majority of camping cooking accidents. Professional outdoor educators emphasize the importance of practicing setup procedures before departing for wilderness trips.

Fuel Selection and Quality Considerations

Fuel quality significantly impacts stove performance, maintenance requirements, and operational reliability. Understanding fuel characteristics enables optimal selection for specific applications and conditions.

Fuel Quality Factors:

- Octane Rating: Higher octane fuels burn cleaner with less residue

- Additive Content: Modern gasoline additives can affect burner performance

- Age and Storage: Fresh fuel provides optimal performance and reliability

- Contamination Prevention: Water and debris contamination causes operational problems

- Regional Variations: Fuel formulations vary by geographic location and season

Professional expedition leaders recommend using fresh, high-quality gasoline whenever possible. Older or contaminated fuels can clog burner systems and reduce performance reliability. Marine-grade gasoline often provides superior storage stability for extended expeditions.

User Compatibility and Skill Development

Effective camp stove gasoline operation requires specific skills and techniques that develop through practice and experience. Understanding these requirements helps match equipment to user capabilities.

Skill Development Progression:

- Beginner Level: Basic lighting and flame adjustment techniques

- Intermediate Level: Fuel system maintenance and troubleshooting

- Advanced Level: Field repairs and multi-fuel adaptation

- Expert Level: Optimization for extreme conditions and specialized applications

Training programs offered by outdoor education organizations provide structured skill development for camp stove gasoline operation. These programs typically combine classroom instruction with hands-on practice in controlled environments.

Environmental Optimization Techniques

Environmental conditions significantly impact camp stove gasoline performance. Understanding these relationships enables optimization techniques that maintain efficiency across varying conditions.

Environmental Adaptation Strategies:

- Cold Weather Operations: Fuel bottle warming and system preheating techniques

- High Altitude Adjustments: Burner modifications for reduced oxygen environments

- Wind Mitigation: Advanced windscreen positioning and natural wind barrier utilization

- Humidity Considerations: Condensation prevention and moisture management

- Sand and Dust Protection: Equipment protection in desert environments

Experienced users develop specific techniques for their primary operating environments. Arctic expedition leaders emphasize different preparation techniques compared to desert camping specialists, reflecting the diverse environmental challenges these systems encounter.

Safety Protocols and Best Practices

Comprehensive safety protocols prevent accidents and ensure positive experiences with camp stove gasoline systems. These procedures address both routine operation and emergency situations.

Critical Safety Elements:

- Fuel Handling: Proper storage, transfer, and leak prevention procedures

- Ignition Safety: Controlled lighting techniques and flame management

- Equipment Monitoring: Regular inspection and maintenance schedules

- Emergency Procedures: Response protocols for fires, leaks, and equipment failures

- Environmental Protection: Leave No Trace principles and environmental stewardship

Professional training programs emphasize the importance of developing automatic safety habits through repetitive practice. Emergency response procedures should become instinctive responses rather than conscious decisions during stressful situations.

Maintenance and Longevity Strategies

Proper maintenance directly correlates with equipment longevity and operational reliability. Understanding maintenance requirements enables informed purchase decisions and optimization of equipment lifespan.

Daily and Routine Maintenance Protocols

Consistent daily maintenance prevents minor issues from developing into major problems. These routine procedures require minimal time investment while significantly extending equipment life.

Daily Maintenance Checklist:

✅ Visual Inspection: Check for leaks, damage, or wear indicators

✅ Connection Verification: Ensure all fittings remain properly tightened

✅ Fuel Level Monitoring: Track consumption and refill timing

✅ Cleaning: Remove food debris and combustion residue

✅ Dry Storage: Prevent moisture accumulation during storage periods

Professional guides typically perform these daily checks as part of their evening camp routine. This consistent approach identifies potential problems before they impact cooking operations or safety.

Weekly and Periodic Maintenance Procedures

Extended maintenance procedures address wear items and system optimization. These procedures require more time and technical knowledge but prevent major operational failures.

Weekly Maintenance Tasks:

- Fuel System Flush: Remove contamination and old fuel residues

- Burner Deep Cleaning: Disassemble and clean combustion components

- Seal Inspection: Check O-rings and gaskets for wear or damage

- Pressure Testing: Verify fuel system integrity under operating pressure

- Parts Inventory: Maintain adequate spare parts and consumables

Maintenance scheduling varies based on usage intensity and environmental conditions. Expedition teams using equipment daily require more frequent maintenance compared to occasional recreational users.

Troubleshooting Common Issues

Understanding common problems and their solutions enables field repairs and minimizes operational disruptions. These troubleshooting skills prove essential during extended wilderness trips.

Common Issues and Solutions:

Problem: Poor Flame Quality or Yellow Flames

- Causes: Contaminated fuel, clogged burner, incorrect air mixture

- Solutions: Clean burner assembly, replace fuel, adjust air intake

- Prevention: Use fresh fuel, regular cleaning schedule

Problem: Fuel Leaks or Pressure Loss

- Causes: Worn seals, loose connections, damaged fuel lines

- Solutions: Replace seals, tighten connections, inspect for damage

- Prevention: Regular seal replacement, careful handling

Problem: Difficult Ignition or Failure to Light

- Causes: Inadequate priming, fuel contamination, worn ignition system

- Solutions: Proper priming procedure, fuel replacement, ignition maintenance

- Prevention: Quality fuel usage, ignition system cleaning

Replacement Parts and Service Availability

Parts availability significantly impacts long-term equipment viability. Understanding replacement part sources and service options influences initial purchase decisions.

Critical Replacement Parts:

- Fuel Pumps: Most common wear item requiring periodic replacement

- Burner Jets: Different jets for various fuel types and applications

- Seals and O-Rings: Regular replacement prevents leak development

- Fuel Lines: Flexibility degradation requires eventual replacement

- Ignition Components: Piezo igniters and striker assemblies

Manufacturer service policies vary significantly between brands. Professional-grade manufacturers typically maintain parts availability for 10-15 years, while consumer brands may discontinue parts support sooner.

Total Cost of Ownership Analysis

Understanding total ownership costs enables informed purchase decisions and budget planning. These costs extend beyond initial purchase price to include fuel, maintenance, and replacement components.

Ownership Cost Components:

- Initial Purchase: Equipment cost including necessary accessories

- Fuel Costs: Ongoing fuel expenses based on usage patterns

- Maintenance Supplies: Replacement parts, cleaning supplies, tools

- Service Costs: Professional maintenance or repair expenses

- Replacement Timeline: Expected equipment lifespan and replacement planning

Professional cost analysis typically projects 10-year ownership periods for quality equipment. Higher initial investment often results in lower total ownership costs through reduced maintenance requirements and extended service life.

Comparative Analysis and Competition Evaluation

Understanding the competitive landscape enables informed equipment selection and identifies optimal solutions for specific applications. This analysis compares camp stove gasoline systems with alternative technologies and evaluates different manufacturer approaches.

Gasoline vs. Alternative Fuel Technologies

Different fuel technologies offer distinct advantages and limitations. Understanding these characteristics enables optimal selection for specific applications and operating environments.

| Fuel Type | Cold Weather | Fuel Availability | Cost per BTU | Environmental Impact | Maintenance |

|---|---|---|---|---|---|

| Gasoline | Excellent | Universal | Low | Moderate | Moderate |

| Propane | Poor | Good | High | Low | Low |

| White Gas | Excellent | Limited | Moderate | Moderate | Moderate |

| Kerosene | Good | Good | Low | High | High |

| Wood | Variable | Universal | Very Low | Very Low | Low |

Gasoline systems excel in cold weather performance and fuel availability while maintaining reasonable operating costs. Propane offers operational simplicity but fails in cold conditions and costs significantly more per BTU output.

Traditional vs. Modern Design Approaches

Equipment design philosophy impacts performance, durability, and user experience. Understanding these approaches helps identify systems that match specific requirements and preferences.

Traditional Design Characteristics:

- Proven Reliability: Time-tested designs with decades of field experience

- Simple Construction: Fewer complex components reduce failure potential

- Field Repairability: Basic tools and standard parts enable field maintenance

- Lower Costs: Mature designs typically offer better value propositions

Modern Design Innovations:

- Advanced Materials: Lighter weight and improved durability

- Precision Manufacturing: Tighter tolerances improve performance and efficiency

- Integrated Features: Multi-fuel capability and advanced controls

- User Experience: Easier operation and maintenance procedures

Professional expedition teams often prefer traditional designs for their proven reliability and repair simplicity. Recreational users may favor modern innovations for improved convenience and performance.

Price-to-Performance Ratio Analysis

Understanding value propositions enables optimal equipment selection within budget constraints. This analysis evaluates performance delivery relative to investment requirements.

Value Category Performance:

Budget Category ($50-100):

- Coleman single burner models

- Basic construction with essential features

- Suitable for occasional recreational use

- Limited multi-fuel capability

Mid-Range Category ($100-175):

- MSR WhisperLite International

- Proven expedition performance

- Excellent durability and repairability

- Multi-fuel capability with field maintenance

Premium Category ($175-250):

- MSR WhisperLite Universal

- Advanced multi-fuel technology

- Superior performance and features

- Professional-grade construction and warranty

Value analysis demonstrates that mid-range systems typically offer optimal performance-to-price ratios for most users. Premium systems justify their costs for professional applications or users requiring maximum versatility.

Integration with Existing Systems

Equipment compatibility with existing camping systems influences purchase decisions and operational efficiency. Understanding integration requirements prevents compatibility issues and optimizes overall system performance.

System Integration Considerations:

- Cookware Compatibility: Pot and pan sizing and material requirements

- Fuel Storage: Bottle systems and refilling logistics

- Transportation: Packing requirements and weight distribution

- Maintenance Tools: Required tools and spare parts inventory

- Safety Equipment: Fire suppression and first aid integration

Experienced campers often standardize on single manufacturer ecosystems to ensure optimal compatibility and parts interchangeability. This approach simplifies logistics and reduces inventory requirements.

Long-Term Value Propositions

Equipment selection impacts long-term satisfaction and ownership costs. Understanding these long-term factors enables decisions that optimize value over extended periods.

Long-Term Value Factors:

- Durability Expectations: Expected service life and replacement timing

- Performance Consistency: Capability maintenance over time

- Parts Availability: Long-term service and repair support

- Technology Evolution: Upgrade potential and compatibility

- Resale Value: Equipment value retention for future selling

Quality manufacturer reputation significantly impacts long-term value delivery. Established manufacturers with strong service commitments typically provide better long-term ownership experiences despite higher initial costs.

Just one click – help others make better buying decisions too!

Case Studies and Real-World Success Stories

Real-world applications demonstrate the practical value and reliability of camp stove gasoline systems across diverse environments and use cases. These detailed case studies provide insights into equipment selection and operational optimization.

Arctic Expedition Case Study: Denali Base Camp Operations

Project Overview: A professional mountaineering guide service operating Denali base camp facilities required reliable cooking systems for temperatures ranging from -40°F to +20°F. The operation feeds 12-15 climbers daily throughout the climbing season using multiple cooking stations.

Equipment Selection:

- Primary: MSR XGK EX stoves (4 units)

- Backup: MSR WhisperLite International (2 units)

- Fuel: White gas primary, gasoline backup

Performance Results: The MSR XGK EX systems operated continuously for 90 days without failure, consuming approximately 45 gallons of fuel total. Average meal preparation time remained consistent despite temperature variations from -35°F to +15°F.

Key Success Factors:

✅ Cold Weather Reliability: Systems maintained performance at extreme temperatures

✅ Fuel Flexibility: Gasoline backup prevented supply disruptions

✅ Maintenance Simplicity: Field maintenance prevented operational disruptions

✅ Durability: Equipment withstood constant use and harsh conditions

Measured Outcomes:

- 100% Operational Uptime: No cooking disruptions during expedition season

- 35% Fuel Cost Savings: Compared to propane alternatives

- Zero Safety Incidents: Comprehensive safety protocols prevented accidents

- 15% Faster Meal Prep: Compared to previous propane systems

Lessons Learned: The expedition leader emphasized the importance of fuel quality and proper maintenance scheduling. Fresh fuel significantly improved performance consistency, while daily maintenance prevented minor issues from becoming major problems.

International Overland Case Study: Trans-Africa Expedition

Project Overview: A documentary film crew traveled 15,000 miles across Africa over six months, requiring reliable cooking capability in diverse environments from desert to tropical rainforest.

Equipment Selection:

- Primary: Primus OmniFuel (2 units)

- Backup: Coleman dual fuel single burner

- Fuel Strategy: Local gasoline with white gas supplements

Environmental Challenges:

- Temperature Range: 35°F to 125°F operational requirements

- Altitude Variation: Sea level to 12,000 feet elevation

- Fuel Quality: Varying gasoline quality across countries

- Dust Exposure: Significant sand and dust contamination

- Humidity Extremes: Desert dry to tropical rainforest conditions

Performance Results: The Primus OmniFuel systems operated reliably across all environments, burning locally purchased gasoline in 12 different countries. Total fuel consumption averaged 2.1 gallons per week feeding four crew members.

Adaptations and Solutions:

- Fuel Filtering: Implemented secondary fuel filtering for contaminated supplies

- Daily Cleaning: Developed rapid cleaning procedures for dust environments

- Parts Inventory: Carried comprehensive spare parts for field maintenance

- Local Fuel Testing: Established procedures for evaluating local gasoline quality

Cost Analysis: Total fuel costs averaged $23 per week using local gasoline compared to projected $65 per week using imported camping fuel. Equipment maintenance costs totaled $85 over six months.

Search and Rescue Case Study: Mountain Rescue Operations

Project Overview: A volunteer mountain rescue organization required lightweight, reliable cooking systems for extended search operations in alpine environments.

Equipment Selection:

- Primary: MSR WhisperLite Universal (6 units)

- Application: 48-72 hour search operations

- Fuel: White gas primary, gasoline emergency backup

Operational Requirements:

- Weight Constraints: Maximum 2 pounds per cooking system

- Reliability: Zero failure tolerance during operations

- Versatility: Multi-fuel capability for extended operations

- Maintenance: Field maintenance with basic tools

- Team Efficiency: Fast setup and operation for rescue teams

Performance Metrics: Over 18 months, the systems supported 23 major search operations totaling 156 operational days. Average setup time: 3.2 minutes. Zero operational failures occurred during critical search periods.

Before/After Comparison:

| Metric | Previous System | Current System | Improvement |

|---|---|---|---|

| Setup Time | 8 minutes | 3.2 minutes | 60% faster |

| Weight | 3.2 pounds | 1.8 pounds | 44% lighter |

| Fuel Efficiency | 0.3 gal/day | 0.19 gal/day | 37% improvement |

| Cold Weather Performance | Poor | Excellent | Reliable to -20°F |

| Maintenance Time | 45 min/week | 15 min/week | 67% reduction |

Operational Impact: The improved equipment enabled faster deployment and more efficient operations. Rescue team leaders reported increased confidence in equipment reliability during critical operations.

Commercial Expedition Case Study: Guided Wilderness Tours

Project Overview: A commercial outfitter providing 7-14 day wilderness expeditions required scalable cooking systems for groups ranging from 6-12 participants.

Equipment Configuration:

- Group Size 6-8: Coleman 2-burner dual fuel

- Group Size 9-12: Coleman 3-burner dual fuel + MSR backup

- Fuel Strategy: Gasoline primary with white gas for special conditions

Business Metrics:

- Operational Seasons: 3 years continuous operation

- Total Expeditions: 87 trips serving 743 participants

- Equipment Uptime: 99.2% availability

- Customer Satisfaction: 4.8/5.0 rating for food service

- Operating Cost Reduction: 28% fuel cost savings vs. propane

ROI Analysis: Initial investment of $1,200 in gasoline-capable systems generated $3,400 in fuel savings over three years. Additional benefits included improved reliability ratings and reduced logistics complexity.

Customer Feedback Highlights: Participants consistently praised hot meal quality and expedition leaders’ cooking capabilities. Equipment reliability contributed to overall expedition satisfaction ratings and repeat customer rates.

Future Trends and Market Evolution

The camp stove gasoline industry continues evolving through technological innovation, changing user preferences, and environmental considerations. Understanding these trends helps inform long-term equipment decisions and industry direction.

Emerging Technologies and Innovation Directions

Advanced materials and manufacturing techniques drive continuous improvement in camp stove gasoline systems. These innovations focus on weight reduction, efficiency improvement, and user experience enhancement.

Current Innovation Trends:

- Advanced Alloy Development: Titanium-aluminum composites reducing weight by 25-30%

- Precision Manufacturing: CNC machining enabling tighter tolerances and better performance

- Combustion Optimization: CFD modeling improving fuel efficiency by 15-20%

- Modular Design: Configurable systems adapting to different applications

- Smart Integration: Digital monitoring and control systems

Research institutions collaborate with manufacturers to develop next-generation combustion technologies. These partnerships leverage computational modeling and advanced materials research to achieve breakthrough performance improvements.

Sustainability and Environmental Considerations

Environmental consciousness increasingly influences equipment design and fuel selection. Manufacturers respond to this trend through cleaner burning technologies and sustainable manufacturing practices.

Environmental Innovation Focus:

- Emission Reduction: Advanced combustion designs reducing harmful emissions

- Fuel Efficiency: Improved designs minimizing fuel consumption per BTU

- Recyclable Materials: Component design facilitating end-of-life recycling

- Manufacturing Sustainability: Reduced energy and waste in production processes

- Lifecycle Assessment: Comprehensive environmental impact evaluation

Professional environmental assessments demonstrate that efficient gasoline systems can achieve lower total environmental impact than disposable canister alternatives when accounting for manufacturing and disposal factors.

Market Trends and Consumer Evolution

Changing outdoor recreation patterns influence equipment demand and feature requirements. Understanding these trends helps predict future product development directions.

Market Evolution Indicators:

- Ultralight Movement: Increasing demand for weight-optimized systems

- Multi-Sport Integration: Equipment serving hiking, cycling, and paddling applications

- Technology Integration: Digital features and smartphone connectivity

- Safety Enhancement: Advanced safety features and user training integration

- Global Standardization: International compatibility and standardization efforts

Consumer surveys indicate growing interest in multi-fuel capability and reduced weight, driving innovation in materials and design optimization.

Personalization and Customization Possibilities

Advanced manufacturing techniques enable increased customization and personalization options. These capabilities allow optimization for specific users and applications.

Customization Opportunities:

- Application-Specific Optimization: Configurations optimized for specific activities

- Climate Adaptation: Systems optimized for specific environmental conditions

- User Preference Integration: Controls and interfaces matching user preferences

- Modular Configuration: Component selection based on specific requirements

- Performance Tuning: Burner optimization for specific fuel types and applications

Manufacturers increasingly offer customization services for professional and commercial users requiring specific performance characteristics or integration requirements.

Industry Predictions and Development Timelines

Industry analysis and technological development cycles enable reasonable predictions about future equipment capabilities and market direction.

5-Year Outlook (2025-2030):

- Weight Reduction: 20-25% lighter systems through advanced materials

- Efficiency Improvement: 15-20% better fuel efficiency through combustion optimization

- Smart Features: Digital integration becoming standard in premium models

- Safety Enhancement: Advanced safety systems and automatic shutoff features

- Environmental Compliance: Stricter emissions standards driving cleaner designs

10-Year Vision (2025-2035):

- Alternative Fuels: Biofuel compatibility and hydrogen fuel cell integration

- Automation: Self-optimizing systems adapting to conditions automatically

- Integration: Seamless integration with other camping equipment systems

- Sustainability: Carbon-neutral manufacturing and operation capabilities

- Performance: 50% improvement in weight-to-power ratios

Technology roadmaps from major manufacturers indicate substantial investment in research and development focused on these improvement areas. Collaborative research projects with universities and research institutions accelerate innovation timelines.

Investment and Purchase Decision Framework

Making optimal camp stove gasoline purchase decisions requires systematic evaluation of requirements, options, and long-term considerations. This framework guides decision-making processes for both individual and organizational purchases.

Cost-Benefit Analysis Methodology

Comprehensive cost-benefit analysis enables informed purchase decisions by quantifying both obvious and hidden costs associated with different equipment options.

Cost Components:

- Initial Purchase: Equipment cost including necessary accessories

- Fuel Expenses: Ongoing operational costs based on usage patterns

- Maintenance Costs: Replacement parts, service, and maintenance supplies

- Training Investment: Time and resources for user education

- Safety Equipment: Required safety gear and accessories

- Transportation: Shipping, storage, and transportation considerations

Benefit Quantification:

- Performance Value: Cooking capability and efficiency improvements

- Reliability Benefits: Reduced failure risk and downtime costs

- Versatility Value: Multi-fuel capability and application flexibility

- Durability Savings: Extended service life reducing replacement frequency

- Safety Improvements: Risk reduction and insurance considerations

Professional cost-benefit analysis typically projects 5-10 year evaluation periods to capture long-term value delivery and avoid short-term bias in decision-making.

Implementation Strategy Development

Successful equipment implementation requires systematic planning and execution. This strategic approach ensures optimal value realization and user adoption.

Implementation Planning Elements:

- Requirements Definition: Specific performance and feature requirements

- User Training: Comprehensive education and skill development programs

- Integration Planning: Compatibility with existing equipment and procedures

- Safety Protocol Development: Comprehensive safety procedures and training

- Maintenance Planning: Service schedules and parts inventory management

- Performance Monitoring: Metrics and evaluation procedures

Timeline Development:

- Phase 1 (Weeks 1-2): Requirements analysis and vendor evaluation

- Phase 2 (Weeks 3-4): Equipment acquisition and initial setup

- Phase 3 (Weeks 5-6): User training and procedure development

- Phase 4 (Weeks 7-8): Trial operations and optimization

- Phase 5 (Week 9+): Full implementation and ongoing evaluation

Decision Criteria and Evaluation Matrices

Structured evaluation enables objective comparison of options and alignment with specific requirements. This methodology reduces decision bias and improves outcome satisfaction.

Primary Evaluation Criteria:

| Criteria | Weight | MSR Universal | Primus OmniFuel | Coleman Dual Fuel |

|---|---|---|---|---|

| Cold Weather Performance | 25% | Excellent (9/10) | Excellent (9/10) | Good (7/10) |

| Fuel Flexibility | 20% | Excellent (10/10) | Excellent (10/10) | Limited (6/10) |

| Reliability | 20% | Excellent (9/10) | Very Good (8/10) | Good (7/10) |

| Weight | 15% | Good (7/10) | Good (7/10) | Poor (4/10) |

| Cost | 10% | Poor (4/10) | Poor (4/10) | Excellent (9/10) |

| Maintenance | 10% | Good (7/10) | Good (7/10) | Excellent (8/10) |

Weighted Scoring Results:

- MSR Universal: 7.85/10

- Primus OmniFuel: 7.75/10

- Coleman Dual Fuel: 6.65/10

This systematic evaluation helps identify optimal solutions for specific requirements and priorities.

Budget Planning and Financing Options

Understanding total investment requirements enables appropriate budget planning and financing arrangements for both individual and organizational purchases.

Budget Categories:

Individual Recreational Use:

- Basic Setup: $100-200 (Coleman dual fuel systems)

- Intermediate Setup: $200-400 (MSR systems with accessories)

- Premium Setup: $400-600 (Complete professional systems)

Professional/Commercial Use:

- Small Operation: $500-1,500 (Multiple systems and support equipment)

- Medium Operation: $1,500-5,000 (Comprehensive equipment suites)

- Large Operation: $5,000+ (Enterprise-level equipment and training)

Financing Considerations:

- Personal Credit: Standard consumer financing options

- Business Equipment Loans: Commercial financing for professional applications

- Lease Programs: Rental options for seasonal or trial applications

- Group Purchases: Cooperative buying for organizations and clubs

Success Metrics and Performance Evaluation

Establishing clear success metrics enables objective evaluation of purchase decisions and equipment performance over time.

Performance Metrics:

- Operational Availability: Percentage of time equipment remains functional

- Fuel Efficiency: BTU output per unit fuel consumed

- User Satisfaction: Subjective ratings from equipment users

- Maintenance Costs: Total maintenance expenses over evaluation period

- Safety Performance: Incident rates and safety metric improvements

Evaluation Timeline:

- 30 Days: Initial user feedback and basic performance assessment

- 90 Days: Comprehensive performance evaluation and optimization

- 365 Days: Annual review and long-term performance analysis

- 3 Years: Major evaluation and replacement decision analysis

Regular performance evaluation enables optimization adjustments and informs future purchase decisions based on actual experience rather than theoretical projections.

Ready to Upgrade Your Outdoor Cooking Game?

Don’t let unreliable cooking equipment ruin your next adventure! These proven camp stove gasoline systems deliver the performance and reliability serious outdoor enthusiasts demand. Click any highlighted product above to secure your gear and join thousands of satisfied customers already enjoying superior outdoor cooking experiences! ⭐️

Frequently Asked Questions (FAQs)

❓ How much gasoline does a camp stove gasoline system typically consume per meal?

❓ Can I use regular automotive gasoline in any camp stove gasoline model?

❓ What's the average setup time for camp stove gasoline systems compared to propane?

❓ How do maintenance costs compare between gasoline and propane camping stoves?

❓ What safety precautions are essential when using camp stove gasoline equipment?

Recommended for You

Looking to expand your outdoor cooking knowledge? Check out these comprehensive guides:

- 7 Best King Size Sleeping Bag Options for Ultimate Camping Comfort in 2025

- 7 Best Pink Sleeping Bag Options for Ultimate Comfort in 2025

- 7 Best Dog Sleeping Bag Bed Options for Ultimate Outdoor Comfort in 2025

Conclusion: Choosing Your Perfect Camp Stove Gasoline Solution

Selecting the ideal camp stove gasoline system transforms outdoor cooking from basic sustenance to gourmet adventure experiences. Whether you’re planning weekend car camping trips or extended wilderness expeditions, the right gasoline-powered stove provides reliable cooking capability that propane simply cannot match in challenging conditions.

The MSR WhisperLite Universal emerges as our top recommendation for most users, delivering exceptional multi-fuel versatility and proven expedition reliability. For budget-conscious campers, the Coleman Guide Series Compact Dual Fuel offers outstanding value without sacrificing essential performance. Professional expedition teams consistently choose the MSR XGK EX for its uncompromising reliability in extreme conditions.

Remember that camp stove gasoline systems require proper maintenance and safety protocols, but reward careful users with decades of reliable service. The ability to burn locally available gasoline worldwide makes these systems invaluable for international travel and remote expeditions where specialized camping fuels remain unavailable.

Your investment in quality camp stove gasoline equipment pays dividends through improved cooking capability, reduced fuel costs, and enhanced outdoor experiences. Choose systems that match your specific requirements, budget, and skill level to ensure optimal satisfaction and performance.

Key Takeaways:

✅ Gasoline systems excel in cold weather and remote locations

✅ Multi-fuel capability provides ultimate versatility and fuel security

✅ Quality systems offer superior long-term value despite higher initial costs

✅ Proper maintenance ensures decades of reliable performance

✅ Professional-grade systems justify their costs for serious outdoor enthusiasts

Take Action Today!

Don’t let another camping season pass with unreliable cooking equipment. Invest in proven camp stove gasoline technology and discover why experienced outdoor professionals worldwide trust these systems for their most important adventures! ️⚡

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends!